Resource Recycling Share Factory

-

Current situation in Japan

Most waste disposal companies are small and local operations that are insufficient to support large manufacturers.

There are more than 200,000 waste disposal and recycling companies in Japan, but most of them are community-based small businesses and often limit themselves to operating on the local level, so they are currently unable to efficiently support large manufacturers on the national level.

-

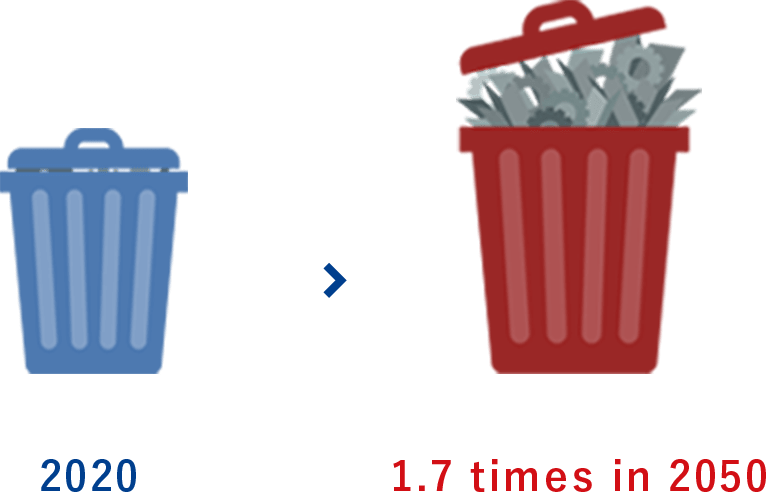

The current state of the world

In 2050, the world’s waste will be 1.7 times the current amount!

A 2018 report by the World Bank predicts that the global waste volume will continue to increase and reach 1.7 times the amount today by the year 2050 if we do not make changes quickly. On the other hand, the demand for raw resources have doubled compared to 40 years ago.

-

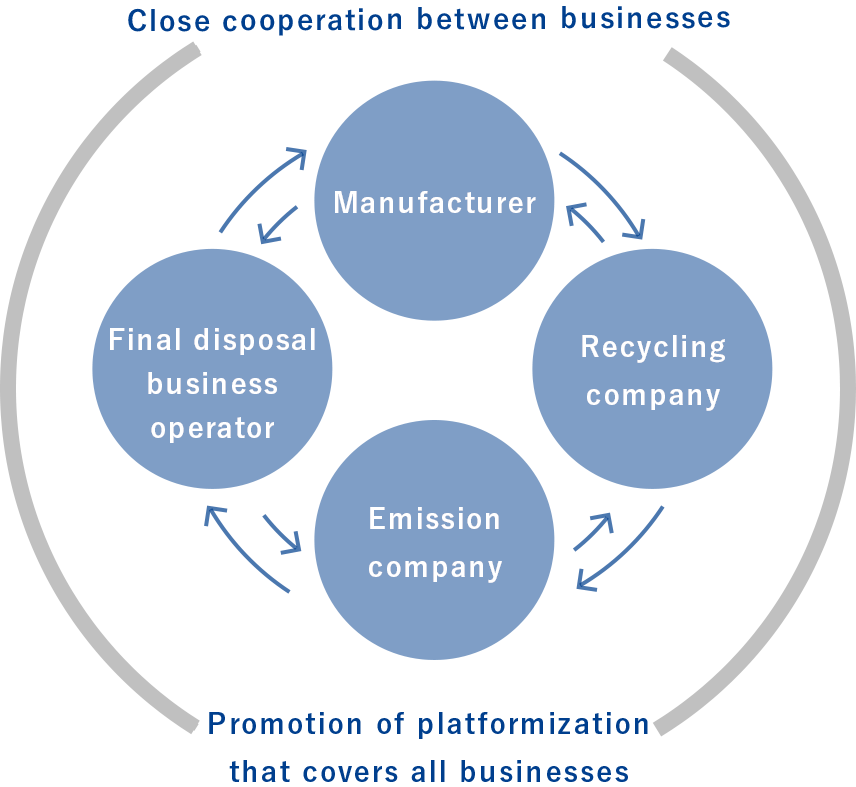

Solidarity of recycling business

Collaboration between manufacturers and resource recycling companies on the basis of manufacturing products that can be recycled is indispensable in creating a sustainable society.

To turn Japan into an advanced recycling and sustainable society, “manufacturers” need to implement Life Cycle Assessment (LCA) which clarifies the environmental impacts of manufacturing, disposal, and recycling, then “design” their products to make them easier to recycle, while “recycling companies” need to develop advanced recycling technology and collaborate closely with manufacturers.

-

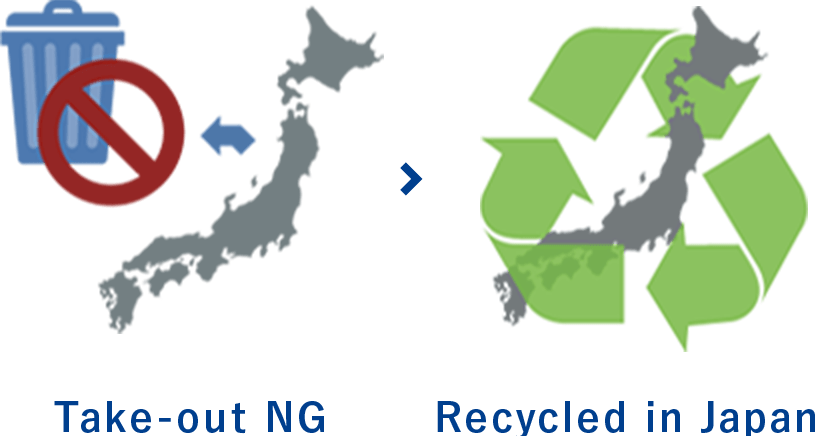

Basel Convention

A mechanism to promote resource recycling is indispensable

As we will not be able to export our waste out of Japan once the Basel Convention is signed, we will need to come up with ways to recycle and reuse the waste within Japan. To create a sustainable society, we will need to limit our use of our domestic natural resources, minimize waste as much as possible, and develop a robust recycling ecosystem.

*Basel Convention: “Regulations on cross-border movement and disposal of waste”

-

Building a platform

What Ilex aims for.

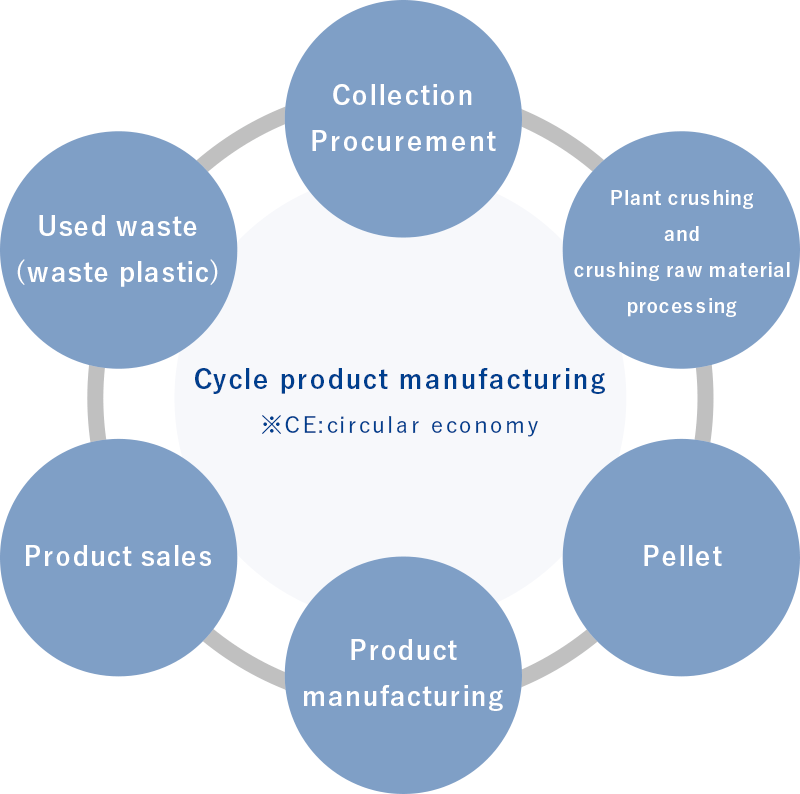

Building a recycling-oriented value chain for resource recycling

IREX is building a platform that integrates the whole sustainable value chain for turning waste into products. We will provide recycling plant equipment, recycling technology, and processing materials to manufacturers while at the same time provide factory management know-hows as well as develop and provide waste management data processing software.

The plastic waste collected will be recycled into raw materials for plastics at our “Resource Recycling Shared Factory” and turned into new products.

- Resource Recycling / Share Factory(Business Model)

- Building a circular value chain that starts with waste and integrates the commercialization of each waste

- Main business activities

-

- Platform building

- R&D

- AI & IT Technology

- Business Design

- Equipment & Instruments

- Factory Construction

- Raw Material Procurement

- Product Sales

- Maintenance

- Mechanical Parts

- Supplies Procurement

- and more